BERTIN WINLIGHT

Design & construction of high-performance optical components

LATEST NEWS

PRODUCT RANGES

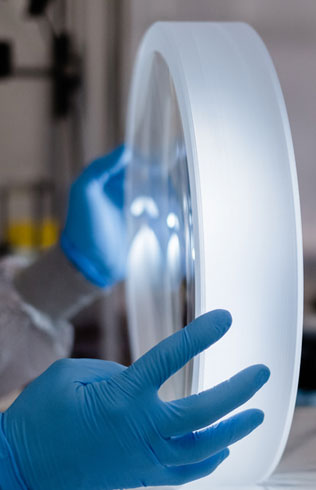

Optical components

Bertin Winlight offers proven expertise in the manufacture of high-precision plano, spherical and aspherical (on-axis, off-axis or free-form) optical components, as well as X-ray mirrors.

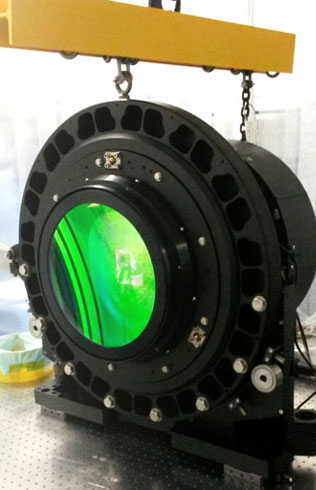

Optronics

By combining our opto-mechanical and electronic skills, we make fully-qualified optronic (electro-optical) products on request.

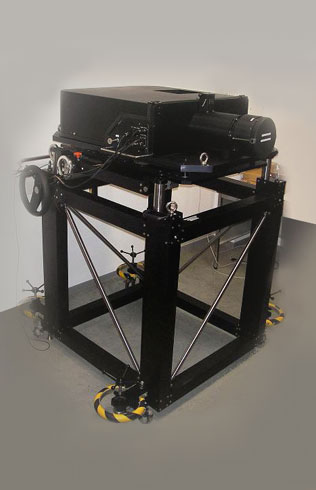

Calibration & test benches

Bertin Winlight designs calibration and test benches (optics and optronics) capable of aligning, checking and qualifying the optical and photonic aspects of high-performance systems.

Spectroscopy & imaging systems

Bertin Winlight contributes to the development of a number of instruments for large telescopes (VLT, ELT, Keck, Gemini, Subaru, etc.)

Instrumentation for plasma experiments

Bertin Winlight designs and builds x-ray microscopes used in plasma diagnostics for large scientific facilities.

BERTIN WINLIGHT, THE HIGH-PERFORMANCE OPTICS COMPANY

Founded in 2001, Bertin Winlight is a French company specialized in the design and construction of high-performance optical components, subassemblies and systems, all compatible with the most demanding environments.

Bertin Winlight primarily operates in the space, defense, synchrotron and astronomy sectors. Its technical expertise is recognized worldwide, spanning the design and construction of optical components, complex subassemblies and high-precision test and calibration benches.

The company’s expertise encompasses all steps in the design, development and production of optical systems, including lenses, mirrors and other unique components. In particular, Bertin Winlight deploys proprietary polishing, assembly and testing technologies.

Bertin Winlight was acquired by Bertin Technologies, in 2017. This link-up bolsters its range of optical and mechanical systems for big science facilities, including synchrotrons, telescopes and research reactors, as well as for major space and defense programs. ISO 9001:2015 certified, Bertin Winlight is committed to providing the highest quality to its customers in Europe, Asia and the United States.